PRODUCTS

* BioEnergo traffic fuels achieve approximately 100%** life cycle greenhouse gas (GHG) saving compared to the fossil fuel reference value of 94 g CO2-eq/MJ given in EU Renewable energy directive II. (**Including CCU CO2 capture)

* BioEnergo traffic fuels achieve approximately 100%** life cycle greenhouse gas (GHG) saving compared to the fossil fuel reference value of 94 g CO2-eq/MJ given in EU Renewable energy directive II. (**Including CCU CO2 capture)

TECHNOLOGY

BioEnergo I is among the first wave of cellulosic 2g bioethanol plants being built in the EU. BioEnergo uses softwood sawdust and woodchips from local Finnish sawmills as raw material.

BioEnergo’s process technology partners are Praj Industries Ltd. (global market leader in 1g and 2g bioethanol production technologies) and Sekab BioFuels & Chemicals AB (pioneer in biorefinery technologies). BioEnergo I technology and process is based on PRAJ’s Enfinity 2nd generation cellulosic ethanol technology which has been in operation at PRAJ’s demo-plant in India since 2009. BioEnergo I technology and process is also based on Sekab’s proven CelluAPP® enzymatic hydrolysis technology which has been in operation at SEKAB’s demo-plant in Sweden since 2004.

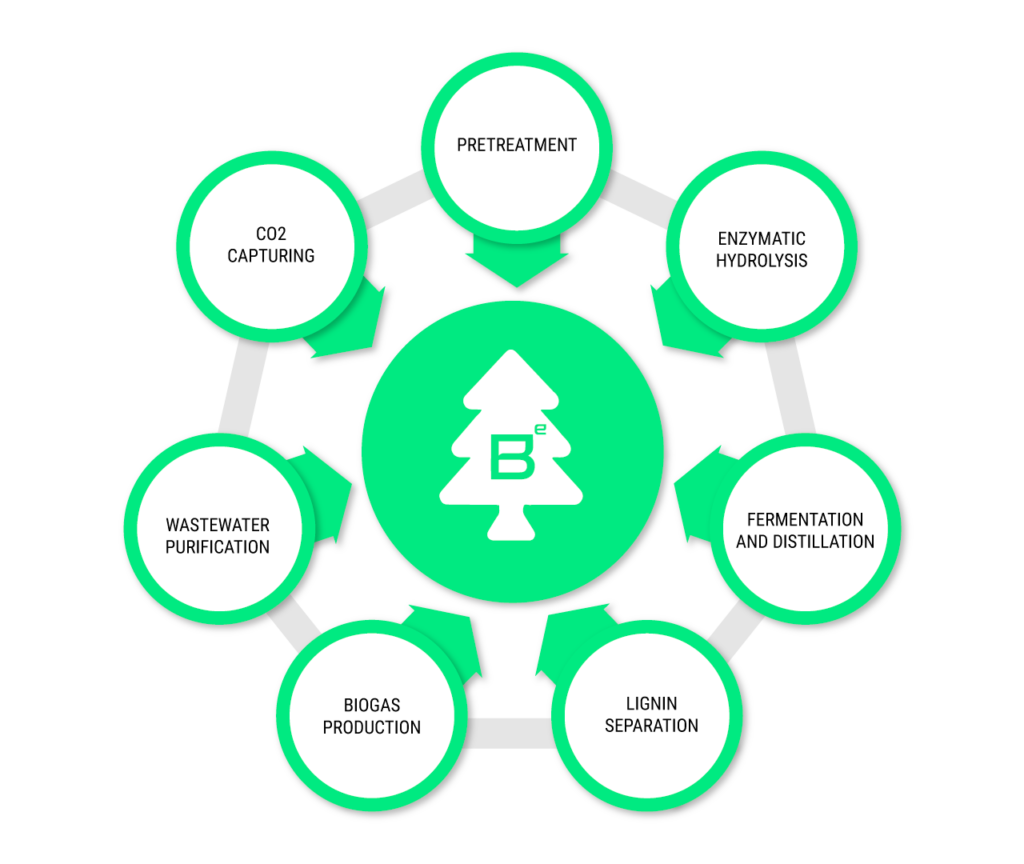

BioEnergo’s production process starts with pre-treatment of softwood sawdust raw material in a steam explosion reactor. This prepares the wood material to receive enzymes. Next step is enzymatic hydrolysis in which the wood material is treated with an enzyme solution that separates and releases valuable sugars from the wood material. Next step is fermentation process in which the released sugars are converted to alcohol (ethanol). Next step is distillation and dehydration in which the alcohol is further refined to transportation fuel grade bioethanol.

As a part of the distillation process stillage consisting of lignin and water is separated. Lignin is diverted to further processing and water is directed to wastewater processing.

Wastewater purification consists of several stages. The first stage is anaerobic treatment (biogas reactors) which produces significant amounts of raw biogas. The raw biogas is captured and processed in a biogas upgrading unit which produces traffic fuel quality biomethane. The biomethane is liquified and transported to customers’ gas fuelling stations.

All CO2 is captured from the process. The CO2 is purified to food grade quality, liquified and then transported to end customers.