TECHNOLOGY

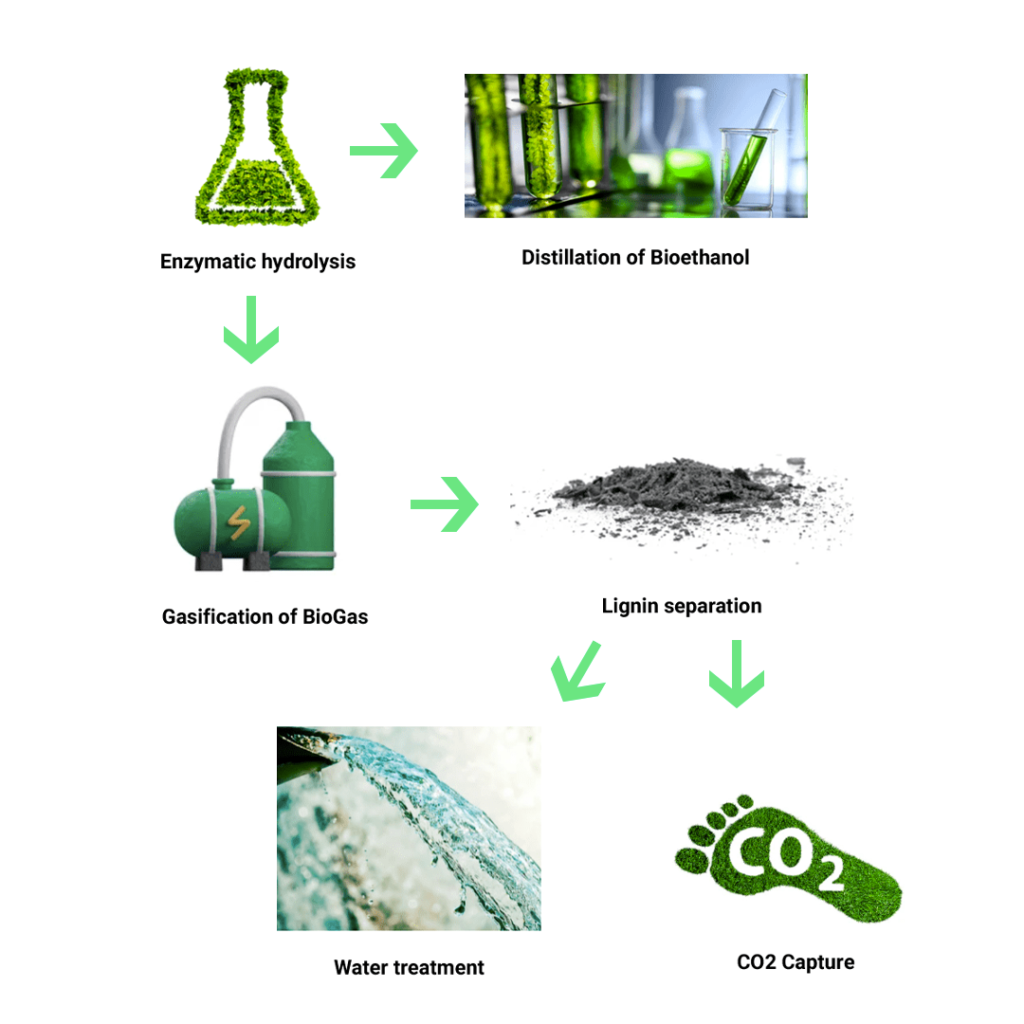

BioEnergo One will be the first industrial scale bioconversion plant on the planet, producing 2nd generation biofuels from softwood sawdust and chips from local Finnish sawmills. The process is based on proven CelluAPP® technology (enzymatic hydrolysis), where pretreated cellulosic biomass is fractionated into cellulosic sugars. Via fermentation the sugars are turned to low alcohol content beer. Lignin is separated and alcohol content is increased in distillation. In dehydration alcohol is further refined to transport fuel grade cellulosic bioethanol. The CelluAPP® technology has been developed and proven at SEKAB demo-plant, that has been operated in Sweden since 2004. The fermentation and distillation technologies are based on PRAJ’s Enfinity 2nd generation cellulosic ethanol technology, that has been continuously developed and operated at PRAJ pilot plant in India since 2009. All CO2 is captured from the process. The green-CO2 from fermentation unit will undergo purification and liquefaction and will be transferred to end customers. The treatment is depending on the application and specified requirements of the end product. Wastewater treatment includes both anaerobic and aerobic treatment. Wastewater will undergo anaerobic treatment in biogas reactor and biogas produced is fed into upgrading and liquefaction to the end product: Liquefied biomethane, which provides low carbon fuels for the heavy transport sectors on land and at sea. Lignin will be separated, dewatered and dried in flash-dryer and after dewatering transported to end customers. The treatment is depending on the application and specified requirements of the end product. BioEnergo is partnering with SEKAB and PRAJ and is committed to develop the process further aiming to utilize process and technology development not only in BioEnergo One, but also in the next BioEnergo’s bioconversion plants.

PROCESS